The longevity and profitability of an offshore field are often determined not by its initial discovery, but by the effectiveness of its ongoing maintenance and optimization. As reservoirs mature, they inevitably face declining pressures, sand production, and the buildup of scale or paraffin, all of which can significantly impede flow. Addressing these issues in the offshore environment has traditionally been an expensive and logistically complex undertaking, often requiring the mobilization of a full drilling rig. However, the emergence of advanced offshore well intervention technologies is revolutionizing this sector, offering more efficient, cost-effective, and flexible ways to maintain and enhance production from the seabed.

The move toward lighter, more agile intervention methods is driven by the need to manage mature offshore wells in an era of tighter margins and increasing technical complexity. In deepwater environments, where rig rates are astronomical, the ability to perform a well intervention from a specialized vessel can save millions of dollars per operation. This has led to a fundamental shift in how offshore well services are conceptualized, moving away from heavy “rig-based” operations toward “vessel-based” interventions that leverage lightweight systems and modular technology. This transformation is essential for ensuring that the world’s maturing offshore basins remain economically viable and continue to contribute to global energy security.

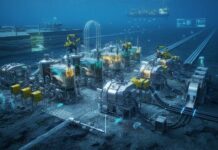

The Rise of Riserless Intervention and Lightweight Systems

One of the most significant breakthroughs in recent years is the development of riserless intervention technology. Traditionally, subsea interventions required a high-pressure riser to connect the wellhead to the surface vessel, providing a conduit for tools and fluids. While effective, the deployment and recovery of a riser system is a time-consuming and weather-dependent process. Riserless Light Well Intervention (RLWI) eliminates this requirement by using a specialized subsea lubricator system that allows tools to be deployed directly from a vessel’s moonpool through the water column and into the well. This drastically reduces the size of the vessel required and the time needed to set up on location, leading to substantial improvements in cost efficiency.

Furthermore, the adoption of lightweight intervention systems is enabling operators to work in deeper waters with smaller, more nimble vessels. these systems utilize advanced composites and high-strength alloys to reduce the weight of the subsea equipment, allowing it to be handled by standard offshore support vessels rather than dedicated heavy-lift rigs. The flexibility of these offshore well intervention technologies allows for a “campaign” approach to well maintenance, where a single vessel can service multiple wells in a region in a single trip. This not only optimizes the logistics of offshore well services but also allows for more frequent interventions, ensuring that wells are always operating at their peak potential.

Advanced Subsea Intervention Systems and Tooling

The success of modern intervention is also dependent on the sophistication of the tools being deployed at the seabed. Modern subsea intervention systems are equipped with a vast array of robotic and electronic capabilities, from autonomous cutters and pullers to high-definition cameras and chemical injection modules. These tools allow for precise tasks such as replacing gas-lift valves, clearing scale blockages, or setting and retrieving plugs. The ability to perform these “mechanical” interventions from a vessel-based system is a major technical achievement that has significantly lowered the threshold for intervening in mature offshore wells.

Moreover, the integration of “intelligent” tooling is providing engineers with unprecedented visibility into the wellbore. By using fiber-optic sensors and real-time data transmission, operators can monitor the progress of an intervention in real-time, adjusting their strategy based on the actual conditions encountered downhole. This reduces the risk of operational failure and ensures that the intervention is conducted with surgical precision. As these subsea intervention systems continue to evolve, they are becoming more capable of handling complex tasks such as wellbore cleanouts and sand management, further extending the productive life of offshore assets.

Enhancing Recovery through Well Stimulation Offshore

Beyond simple maintenance, offshore well intervention technologies are increasingly focused on active production enhancement. Well stimulation offshore involves the injection of chemicals, acid, or high-pressure fluids into the reservoir to increase its permeability and “stimulate” flow. Historically, this required large, specialized stimulation vessels or the installation of permanent injection facilities. Today, however, modular stimulation packages can be deployed from a standard PSV, allowing for more frequent and targeted treatments of mature offshore wells.

Acid stimulation is particularly effective for carbonate reservoirs, where it can dissolve blockages and create new flow paths near the wellbore. Hydraulic fracturing, while more complex, is also being adapted for the offshore environment, allowing for the exploitation of tighter rock formations. The ability to conduct these treatments from a flexible, vessel-based platform is a key driver of efficiency, as it allows operators to respond quickly to changes in well performance. By maintaining the health of the “near-wellbore” area through regular stimulation, companies can significantly increase the total recovery factor of a field, maximizing the return on their initial investment.

Managing the Challenges of Mature Offshore Wells

Mature fields present a unique set of challenges for intervention. Aging infrastructure, declining pressures, and the potential for structural degradation mean that every intervention must be carefully planned and executed. Offshore well intervention technologies in these environments focus heavily on well integrity management ensuring that the barriers that prevent leaks and blowouts remain intact. This includes the use of subsea leak detection systems, cement evaluation tools, and casing repair techniques that can be deployed without pulling the entire production string.

The “plug and abandonment” (P&A) phase is also a major focus for modern intervention services. As wells reach the end of their economic life, they must be safely and permanently sealed to protect the environment. Traditionally, P&A was a massive cost center for operators, often requiring a full drilling rig. However, the development of riserless and vessel-based P&A techniques is significantly lowering these costs, allowing for more efficient decommissioning of mature offshore wells. By integrating P&A into a broader intervention campaign, operators can manage their late-life liabilities more effectively, ensuring a responsible exit from the field.

Digitalization and the Future of Offshore Well Services

The digital revolution is playing a transformative role in the evolution of offshore well intervention technologies. The use of digital twins virtual models of the well and the intervention equipment allows engineers to simulate complex operations before they are performed in the field. This identifies potential risks and bottlenecks in a virtual environment, significantly reducing the likelihood of operational delays or safety incidents. Furthermore, the application of machine learning to historical intervention data is providing new insights into which treatments are most effective for specific reservoir conditions.

Remote operations are another major trend. Modern intervention vessels are increasingly equipped with high-bandwidth satellite links that allow experts on shore to control subsea tools and monitor data in real-time. This reduces the number of personnel required on-site, improving safety and lowering costs. As autonomous underwater vehicles (AUVs) and robotic systems become more capable, the prospect of “unmanned” interventions is moving closer to reality. These digital advancements are turning offshore well services into a high-tech, data-driven discipline that is essential for the future of the energy industry.

Conclusion: Sustaining the Global Offshore Energy Mix

In conclusion, the advancement of offshore well intervention technologies is a vital component of the industry’s effort to maximize the value of existing offshore assets. By embracing riserless intervention, lightweight systems, and digital integration, operators are overcoming the immense technical and economic challenges of maintaining mature offshore wells. These innovations are not only improving production efficiency but are also enhancing the safety and environmental performance of the entire subsea sector.

As the global energy transition continues, the ability to squeeze every possible drop of value from existing reservoirs will be more important than ever. The offshore well intervention technologies developed today will provide the foundation for a more sustainable and efficient energy system, ensuring that the industry can continue to provide reliable energy while minimizing its environmental footprint. The journey of innovation in well services is ongoing, but the progress made in recent years demonstrates that through collaboration and the relentless pursuit of technological excellence, even the most mature fields can have a long and productive future.