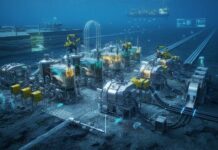

The global maritime energy sector relies on a vast and invisible network of subsea pipelines to transport hydrocarbons from remote offshore fields to coastal processing facilities. Ensuring the long-term reliability of these assets requires a sophisticated discipline known as offshore pipeline integrity and flow assurance. This field is currently undergoing a period of rapid evolution, driven by the move into deeper waters, the development of more complex reservoirs, and an intensified focus on environmental stewardship. Managing the structural health of the pipe while simultaneously ensuring the steady, unobstructed flow of fluids is a dual challenge that requires a holistic approach, blending advanced materials science with real-time digital monitoring and chemical engineering.

The primary threats to subsea pipelines are manifold, ranging from the corrosive effects of seawater and internal fluids to the physical stresses of the deep-ocean environment. Furthermore, the thermodynamic challenges of transporting warm fluids through near-freezing seabed temperatures create a constant risk of solid deposits, such as hydrates or wax, which can lead to catastrophic blockages. To combat these issues, the industry is adopting a suite of new technologies that emphasize “proactive” rather than “reactive” management. This transition is essential for protecting the multi-billion-dollar investments represented by modern offshore projects and for preventing the environmental damage associated with pipeline failure.

Advancements in Offshore Corrosion Monitoring and Material Selection

Internal and external corrosion remains the single greatest threat to the structural life of subsea pipelines. Modern offshore corrosion monitoring has evolved from periodic manual checks to continuous, sensor-based systems that provide real-time data on the rate of metal loss. These systems utilize ultrasonic and electromagnetic sensors permanently mounted at critical locations, such as bends and weld joints, where corrosion and erosion are most likely to occur. By feeding this data into predictive models, operators can adjust chemical inhibition rates in real-time, ensuring that the pipe is protected without the excessive use of expensive chemicals.

In addition to monitoring, the selection of materials is becoming more specialized. For pipelines carrying highly corrosive fluids, such as those with high CO2 or H2S content, the industry is increasingly turning to corrosion-resistant alloys (CRAs) or bimetallic “clad” pipes. These materials offer superior resistance but come at a higher capital cost, requiring careful economic evaluation during the project’s design phase. Furthermore, innovations in external coatings and cathodic protection systems are extending the life of carbon steel pipes in deepwater environments where traditional maintenance is difficult. The goal of modern offshore pipeline integrity and flow assurance is to create a multi-layered defense system that ensures the pipe remains fit for purpose for decades.

Innovations in Offshore Pipeline Inspection Technology

Periodic inspection is a regulatory and operational requirement for all subsea pipelines. Historically, this involved the use of remotely operated vehicles (ROVs) tethered to expensive surface support vessels. However, the trend is moving toward the use of autonomous underwater vehicles (AUVs) and “resident” robotic systems that live on the seabed near the pipeline. These advanced vehicles can perform high-resolution visual and acoustic inspections without the need for a constant human pilot, significantly reducing the cost and frequency of surveys. Modern AUVs are equipped with side-scan sonar and laser profilers that can detect minute changes in the pipeline’s position or the surrounding seabed, such as the emergence of free spans where the pipe is no longer supported.

Internal inspection, often referred to as “pigging,” is also seeing significant innovation. Modern “smart pigs” are equipped with high-resolution sensors that can detect internal cracks, pits, and deformations with sub-millimeter accuracy. These tools are becoming more capable of traversing long distances and navigating complex pipeline geometries, providing a comprehensive “health check” of the internal surface. The integration of this inspection data with real-time offshore corrosion monitoring data allows for the creation of highly accurate digital twins, providing a complete and transparent record of the pipeline’s integrity throughout its lifecycle. This transparency is vital for satisfying regulatory bodies and for making informed decisions about life extension.

Strategic Approaches to Flow Assurance Offshore

Flow assurance offshore is the science of ensuring that the fluids produced at the wellhead reach the processing facility in a steady and predictable manner. As production moves into deeper and colder waters, the risk of hydrate and wax formation increases exponentially. Hydrates ice-like crystals that form when gas and water mix at low temperatures and high pressures can block a pipeline in a matter of hours, leading to dangerous pressure build-ups and long periods of lost production. Managing this risk requires a combination of thermal insulation, chemical injection, and sophisticated pressure management.

Modern hydrate prevention systems are moving beyond the traditional method of continuously injecting large volumes of methanol or glycol. Instead, operators are increasingly using “kinetic hydrate inhibitors” (KHIs) and “anti-agglomerants” (AAs), which are effective in much smaller quantities and are more environmentally friendly. Additionally, active heating technologies, such as “pipe-in-pipe” systems with electrical trace heating, are becoming more common for long-distance tie-backs. These systems allow operators to keep the fluids above the hydrate formation temperature even during long shutdowns, providing a level of operational flexibility that was previously unattainable. The ability to manage these thermodynamic risks is a cornerstone of offshore pipeline integrity and flow assurance.

The Role of Digital Twins in Predictive Management

The integration of digital technology is perhaps the most transformative trend in the management of subsea pipelines. A digital twin is a virtual replica of the physical pipeline that is updated in real-time with data from sensors, inspection reports, and operational history. By using these models, engineers can simulate various operational scenarios such as a sudden change in flow rate or a temperature drop and predict how the pipeline will react. This allows for the optimization of flow assurance offshore strategies, such as determining the exact amount of inhibitor needed for a specific production profile.

Digital twins also play a critical role in integrity management by allowing for “what-if” analysis of structural damage. If an AUV detects a small dent or a localized area of corrosion, the digital twin can be used to perform a high-fidelity stress analysis to determine if the pipeline can continue to operate safely at its current pressure. This reduces the need for emergency repairs and avoids unnecessary production shutdowns, providing significant economic benefits. As AI and machine learning become more sophisticated, these digital models will become even more predictive, identifying subtle trends in the data that could signal the onset of a problem long before it is detectable by traditional means.

Environmental and Regulatory Drivers for Integrity Management

The environmental consequences of a subsea pipeline failure are catastrophic, leading to extensive ecological damage and massive financial liabilities. Consequently, the regulatory landscape for offshore pipeline integrity and flow assurance is becoming increasingly stringent. Governments and international bodies are demanding more frequent inspections, better documentation, and the adoption of best-available technologies for leak detection and corrosion monitoring. For operators, maintaining a robust integrity management program is not just about asset protection; it is a vital part of maintaining their “social license to operate.”

Leak detection technology is a major focus of these regulatory efforts. Modern systems utilize a combination of fiber-optic acoustic sensors, mass-balance calculations, and underwater chemical sniffers to identify leaks with extreme precision. These systems are designed to detect even the smallest “seeps,” allowing for rapid intervention before a minor issue becomes a major spill. By aligning their integrity management programs with these evolving standards, operators can demonstrate a deep commitment to environmental protection and operational excellence. The focus on sustainability is turning subsea pipelines into some of the most monitored and well-managed industrial assets in the world.

Conclusion: The Future of Subsea Transport

In conclusion, the evolution of offshore pipeline integrity and flow assurance is a vital component of the industry’s continued success in deep and challenging waters. By embracing advanced materials, real-time offshore corrosion monitoring, and sophisticated digital twins, operators are building a more resilient and reliable infrastructure for global energy transport. The integration of integrity and flow assurance into a single, cohesive management strategy is essential for navigating the technical and economic complexities of modern offshore development.

As the industry continues to push the boundaries of what is possible, the focus must remain on the relentless pursuit of technological excellence and environmental responsibility. The subsea pipelines of the future will be more than just conduits for hydrocarbons; they will be intelligent, self-monitoring systems that are capable of adapting to changing conditions and identifying threats in real-time. By investing in these trends today, the offshore sector is ensuring a safe and sustainable energy supply for the world, proving that even the most invisible parts of our infrastructure can be the most advanced.