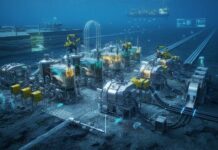

The global offshore energy industry is currently facing a period of intense pressure to improve its capital efficiency and reduce the time required to bring new projects online. In response to these challenges, the use of modular offshore facilities has emerged as a cornerstone of modern development strategies. Traditionally, offshore platforms were largely “stick-built” at the site or involves massive, integrated topsides that required the world’s largest heavy-lift vessels for installation. Today, however, the industry is pivoting toward a more modular approach, where complex systems are broken down into smaller, standardized “prefabricated offshore units” that can be built in parallel at various onshore yards. This shift is fundamentally reshaping the economics of offshore project delivery, offering a more predictable, safer, and cost-effective way to build maritime infrastructure.

The primary driver of this transformation is the desire for offshore CAPEX reduction. By moving a significant portion of the work from the high-cost, high-risk offshore environment to controlled onshore facilities, operators can achieve massive savings in labor and logistics. Onshore fabrication allows for the use of specialized tools, better quality control, and a more stable workforce, all of which contribute to higher productivity and lower costs. Furthermore, modular offshore facilities allow for “plug-and-play” integration at the offshore site, drastically reducing the time required for offshore commissioning—the most expensive phase of any project.

The Strategic Advantages of Offshore Modular Construction

Offshore modular construction offers a range of strategic advantages that go beyond simple cost savings. One of the most significant is the ability to de-risk the project schedule. In traditional construction, any delay in the foundational work can stop the entire project. In a modular approach, different modules such as power generation, water treatment, and compression can be built simultaneously at different specialized yards around the world. This parallel processing significantly compresses the overall project timeline, allowing for “first oil” or gas to be achieved months, or even years, earlier than with traditional methods.

Moreover, the modular approach facilitates greater standardization. By using common modular platforms and designs across multiple projects, operators can achieve significant economies of scale and reduce the complexity of their engineering and procurement. This standardization also simplifies the long-term maintenance and spare parts management of the facility, as many of the components are identical across the fleet. The move toward modular offshore facilities is, in many ways, an evolution toward an “industrialized” model of energy production, where the focus is on technical repeatability and operational excellence rather than unique, bespoke engineering solutions.

Innovations in Offshore Engineering Design for Modularity

The transition to a modular model requires a fundamental shift in offshore engineering design. Engineers must now design with the “end-to-end” logistics in mind, ensuring that each module is appropriately sized and weighted for transport and installation. This often involves the use of sophisticated “building block” architectures, where each module is a self-contained unit with its own structural support and standardized interfaces for power, fluids, and communication. The ability to design these complex interfaces with millimeter precision is a hallmark of modern modular engineering, ensuring that everything fits together perfectly when the modules arrive at the offshore site.

Digital tools are essential for this precision. The use of Building Information Modeling (BIM) and digital twins allows for the virtual “assembly” of the entire facility before a single piece of steel is cut. This identifies potential clashes and integration issues in a virtual environment, preventing expensive rework in the yard or at sea. Furthermore, modular platforms are increasingly designed for “scalability,” allowing for the easy addition of new modules as field conditions change or as production levels grow. This flexibility is vital for managing the uncertainties of long-term reservoir performance, providing a more resilient and adaptable energy infrastructure.

Maximizing Quality and Safety through Prefabricated Offshore Units

Safety is a primary concern in any offshore project, and modular offshore facilities provide a significant safety benefit by reducing the amount of “man-hours” spent in the offshore environment. Offshore work is inherently more hazardous due to the movement of the sea, the height of the structures, and the limited space for equipment and personnel. By moving the bulk of the construction, welding, and testing to onshore yards, operators can significantly reduce the exposure of their workforce to these risks. Onshore yards also offer more controlled environmental conditions, leading to higher quality welds, better coating applications, and more rigorous testing of critical systems.

The use of prefabricated offshore units also allows for more extensive “pre-commissioning” in the yard. In many cases, entire systems can be fully tested and certified before they ever leave the shore. This “flawless start-up” approach ensures that when the modules are finally connected offshore, they are ready for immediate operation. This reduces the number of personnel required on the platform during the critical start-up phase, further enhancing safety and reducing logistical costs. The focus on quality and safety that defines modular offshore facilities is a key driver of their widespread adoption by the world’s leading energy companies.

Logistical Considerations and Heavy-Lift Installation

While modularization reduces offshore work, it introduces its own set of logistical challenges. Transporting massive, complex modules from onshore yards to remote offshore sites requires careful planning and the use of specialized heavy-lift vessels and transport barges. The coordination of these maritime movements is a critical part of the project management process, as any delay in the arrival of a module can disrupt the entire installation sequence. Offshore project managers must balance the benefits of larger, more integrated modules against the limitations of the available transport and installation fleet.

The development of “modular-friendly” installation techniques is helping to overcome these hurdles. For example, the use of “float-over” installations where a barge carrying the topside modules is floated over the jacket and then ballasted down allows for the installation of very large modules without the need for massive cranes. Similarly, the use of modular jackets and subsea foundations is extending the benefits of prefabrication to the entire structure. By optimizing the “logistics-to-installation” chain, operators can ensure that the benefits of modular offshore facilities are fully realized, providing a more efficient and predictable path to project delivery.

Modularization as a Path to Sustainable Offshore Development

The move toward modular offshore facilities is also aligned with the industry’s broader sustainability goals. Modular construction is inherently more resource-efficient than traditional methods, with less waste of materials and energy in the fabrication process. Onshore yards can also be equipped with better waste management and recycling systems than offshore construction sites. Furthermore, the ability to “re-use” modules or even entire modular platforms on different fields at the end of their initial life is a major step toward a circular economy in the offshore sector.

Decommissioning is also made easier and safer by modular design. At the end of a field’s life, the modules can be disconnected and removed in the reverse order of their installation, potentially allowing for the refurbishment and resale of high-value components. This reduces the total “environmental footprint” of the project and lowers the long-term liabilities for the operator. By integrating sustainability into the core of the engineering and construction process, the offshore industry is proving that it can meet the world’s energy needs while also being a responsible steward of the marine environment. Modularization is not just a cost-saving measure; it is a vital tool for the future of sustainable energy production.

Conclusion: The Future of Offshore Infrastructure

In conclusion, the adoption of modular offshore facilities is a transformative trend that is reshaping the global energy industry. By leveraging prefabrication, standardization, and advanced engineering design, operators are achieving significant offshore CAPEX reduction and improving the safety and quality of their projects. The shift toward a modular model is essential for navigating the economic challenges of modern energy development and for building a more resilient and sustainable infrastructure for the future.

As technology continues to advance, the level of modularization will only increase. We are already seeing the emergence of “all-modular” subsea factories and autonomous floating production units that are designed from the ground up for rapid deployment and relocation. The journey toward a more modular and industrialized offshore sector is well underway, and its impact on project delivery and operational efficiency will be far-reaching. By embracing the principles of modular offshore facilities, the industry is setting a new standard for excellence in maritime engineering, ensuring that it remains a vital and competitive force in the global energy mix for decades to come.