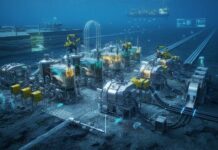

The global offshore energy industry is undergoing a paradigm shift as it ventures into ultra-deep waters and increasingly complex geological formations. Central to this evolution is the development and deployment of subsea processing systems, a suite of technologies that move production and treatment functions from the surface directly to the seafloor. Traditionally, all processing including the separation of oil, gas, and water was performed on massive, expensive offshore platforms. Today, however, the “subsea factory” concept is becoming a reality, allowing for more efficient, cost-effective, and sustainable extraction. By processing fluids at the source, operators are overcoming the technical barriers of distance and pressure, fundamentally transforming how reservoirs are managed and optimized.

The move toward deepwater processing is driven by a combination of technical necessity and economic opportunity. In deepwater environments, the energy required to pump heavy, multi-phase fluids from the seabed to a distant platform is immense. Furthermore, as reservoirs mature and water production increases, the topside processing capacity often becomes a bottleneck. Subsea processing systems solve these problems by handling the heaviest and most energy-intensive tasks at the seabed, allowing for longer tieback distances and significantly higher recovery rates. This transformation is essential for the future of the maritime energy sector, ensuring that complex and remote resources can be developed responsibly and profitably.

The Critical Role of Subsea Boosting Systems

As a reservoir’s natural pressure declines, the flow of hydrocarbons to the surface slows, eventually reaching a point where production is no longer economically viable. Subsea boosting systems are designed to overcome this challenge by providing the necessary “lift” directly at the wellhead. These systems utilize high-capacity multiphase pumps that can handle mixtures of oil, gas, and water, pushing the fluids through long subsea pipelines to the processing facility. This technology is a cornerstone of offshore production enhancement, allowing operators to maintain high production levels even as field pressure drops, effectively extending the productive life of the asset by several years.

The impact of subsea boosting on reservoir performance is profound. By lowering the back-pressure on the wellbore, boosting allows for a more efficient drainage of the reservoir, increasing the ultimate recovery factor. Furthermore, the ability to boost production over long distances enables the development of satellite fields that are too small to justify their own platform. These “marginal” fields can be tied back to an existing hub located tens or even hundreds of kilometers away, significantly improving the overall project economics. The continuous innovation in pump design and subsea power distribution is making these subsea boosting systems more reliable and efficient, even in the most hostile marine environments.

Enhancing Recovery with Subsea Separation Technology

One of the most transformative elements of the subsea factory is subsea separation technology. This involves separating the produced fluids into their constituent parts oil, gas, water, and solids directly on the seafloor. By removing the water at the seabed, operators can avoid the cost and energy of pumping it to the surface, where it would otherwise take up valuable space in the topside processing modules. The separated water can then be reinjected into the reservoir or a disposal well at the seabed, providing the dual benefit of pressure support and environmental protection.

The removal of solids, such as sand, at the seabed is also a critical aspect of flow assurance. Sand can be highly abrasive, causing significant damage to subsea pipelines and pumps if not managed properly. Subsea separation systems equipped with sand-handling modules ensure that only clean fluids are transported to the surface, reducing the risk of equipment failure and extending the life of the infrastructure. Furthermore, subsea gas-liquid separation allows for the separate transport of gas and liquids, which can be more efficient and easier to manage in long-distance tiebacks. This level of offshore reservoir optimization is essential for maximizing the value of complex deepwater fields.

The Economic and Operational Benefits of Deepwater Processing

The adoption of subsea processing systems offers a range of economic and operational advantages that go beyond simple production increases. One of the most significant is the reduction in topside weight and space. By moving processing modules to the seafloor, operators can use smaller and less expensive floating production units (FPSOs) or platforms. This offshore CAPEX reduction is a major driver of project viability, particularly in a world of volatile energy prices. Additionally, the modular nature of subsea systems allows for “scalable” development, where processing capacity can be added incrementally as the field grows, reducing the initial investment risk.

Operationally, subsea processing improves the overall efficiency and reliability of the production system. Because the fluids are processed near the wellhead, the risk of hydrate formation and wax deposition in the pipelines is significantly reduced. This improves flow assurance and reduces the need for continuous chemical injection. Furthermore, subsea systems are inherently protected from surface weather conditions, such as hurricanes or ice, allowing for more consistent production in challenging environments. The ability to monitor and control these systems in real-time from an onshore control center is a vital part of the digital oilfield offshore, providing operators with the visibility and agility needed to optimize performance continuously.

Technical Innovation and the Future of the Subsea Factory

The future of subsea processing systems is defined by the relentless pursuit of technical excellence and integration. We are seeing the emergence of “all-electric” subsea factories, which replace traditional hydraulic systems with more efficient and controllable electrical alternatives. This reduces the weight and complexity of the subsea infrastructure and allows for faster response times. Additionally, the development of high-voltage subsea power distribution systems is enabling the deployment of larger and more powerful boosting and separation modules in deeper waters.

Digitalization is also playing a key role, with AI and machine learning being used to optimize the operation of subsea processing units. Predictive maintenance algorithms can identify the early signs of pump wear or sensor drift, allowing for planned interventions before a failure occurs. This is particularly important for subsea systems, where intervention is expensive and logistically complex. Furthermore, the integration of subsea processing with “smart” well completion technology is allowing for more precise reservoir management, with the ability to adjust injection and production rates at the wellhead based on real-time data from the subsea factory. This synergy represents the pinnacle of modern maritime energy engineering.

Environmental Stewardship and Sustainable Production

Subsea processing systems are a vital tool for achieving the industry’s sustainability goals. By enabling the direct reinjection of produced water and solids at the seabed, these systems minimize the risk of surface contamination and reduce the energy intensity of production. Furthermore, the ability to develop remote fields using long tiebacks reduces the number of surface platforms required, minimizing the overall “footprint” of the offshore development. This focus on sustainable production is essential for maintaining the industry’s social license to operate and for meeting increasingly stringent environmental regulations.

Additionally, subsea processing can play a role in the energy transition. The expertise gained in subsea separation and injection is directly applicable to carbon capture and storage (CCS) projects, where CO2 must be handled and stored safely in offshore reservoirs. Subsea factories could eventually be used to process and sequester carbon from other industrial sources, turning the offshore energy industry into a leader in climate mitigation. By aligning technological innovation with environmental responsibility, the sector is proving that it can be a part of the solution to the world’s most pressing challenges.

Conclusion: Unlocking the Potential of the Ocean Floor

In conclusion, subsea processing systems are transforming the maritime energy landscape, turning what was once considered “unreachable” into a productive and sustainable resource. By moving boosting, separation, and treatment functions to the seafloor, operators are overcoming the immense technical and economic challenges of deepwater development. This transformation is not just about incremental improvements; it is a fundamental shift in how we approach offshore energy production, emphasizing efficiency, reliability, and environmental stewardship.

As the industry continues to innovate, the “subsea factory” will become an increasingly common sight on the ocean floor, providing a cleaner and more efficient path to global energy security. The journey of innovation in subsea processing is far from over, but the progress made in recent years is a testament to the ingenuity and resilience of the offshore sector. By investing in these technologies today, the industry is ensuring its continued success and relevance for decades to come, proving that the future of energy is not just on the horizon, but beneath the waves.