Key Takeaways:

- Overcoming offshore project execution challenges requires a fundamental shift toward integrated project delivery models that prioritize transparency and collaboration between operators and contractors. By utilizing advanced digital project management tools and implementing rigorous offshore execution risks assessments, companies can better manage the volatility of oil gas EPC projects, ensuring that complex infrastructure is delivered on time and within budget while maintaining the highest possible safety performance across all maritime operations.

- The achievement of effective offshore cost control is increasingly dependent on the standardization of equipment and the early involvement of supply chain partners in the design phase. This proactive approach minimizes the potential for expensive late-stage changes and schedule delays, allowing for a more resilient project lifecycle that can withstand the economic pressures of the global energy market. By focusing on streamlined project delivery, the industry can improve the long-term profitability of offshore assets while ensuring environmental and regulatory compliance.

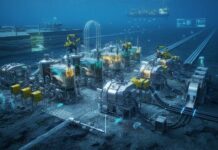

The delivery of large-scale offshore energy infrastructure is widely recognized as one of the most complex engineering and logistical tasks in the modern industrial world. Characterized by multi-billion-dollar investments, remote maritime environments, and the coordination of thousands of international personnel, these projects are inherently susceptible to a wide array of offshore project execution challenges. In an era of volatile energy prices and increasing regulatory scrutiny, the ability to manage these complexities effectively is no longer just a competitive advantage it is a prerequisite for survival. Successfully bringing an offshore field from discovery to first production requires a sophisticated blend of technical expertise, financial discipline, and a relentless focus on risk mitigation.

At the core of these challenges is the inherent uncertainty of the offshore environment. Weather conditions, subsea geological surprises, and the logistical difficulties of working hundreds of kilometers from shore can all disrupt even the most meticulously planned schedules. Furthermore, the specialized nature of oil gas EPC (Engineering, Procurement, and Construction) projects means that any delay in one part of the chain can have a cascading effect on the entire project timeline. To navigate these hurdles, the industry is moving away from traditional, fragmented delivery models toward more integrated and collaborative approaches that emphasize transparency and shared responsibility.

Mitigating Offshore Execution Risks in EPC Projects

The management of offshore execution risks is a continuous process that begins long before the first steel is cut. Successful project teams conduct comprehensive risk assessments during the initial feasibility and design stages, identifying potential bottlenecks in the supply chain, technical gaps in the engineering, and risks to personnel safety. In the context of oil gas EPC projects, these risks are often compounded by the need to coordinate multiple large-scale contractors across different geographies. Implementing a robust project management framework that utilizes real-time data and predictive analytics allows for the early detection of issues, enabling teams to take corrective action before a problem escalates into a major schedule delay.

One of the most effective solutions for mitigating execution risk is the adoption of “digital project delivery” systems. These platforms integrate design, procurement, and construction data into a single, cloud-based environment, providing all stakeholders with a “single source of truth.” This visibility is crucial for managing the complex interfaces between different modules of an offshore platform or subsea system. By using digital twins to simulate the construction and installation process, engineers can identify and resolve clashes in a virtual environment, significantly reducing the likelihood of expensive rework in the field. This digital-first mindset is fundamentally reshaping the efficiency of offshore project management.

Implementing Effective Offshore Cost Control

Maintaining offshore cost control is perhaps the greatest challenge facing project managers in today’s economic climate. The high capital intensity of offshore developments means that even small percentage overruns can translate into hundreds of millions of dollars in additional costs. The primary drivers of cost escalation are often late-stage design changes, supply chain disruptions, and the “inflation” of service and equipment prices. To combat these pressures, the industry is increasingly turning to standardization as a means of reducing complexity and cost. By using “off-the-shelf” designs and components for platforms and subsea systems, operators can achieve significant economies of scale and reduce the time required for engineering and procurement.

Effective cost control also requires a more collaborative relationship with the supply chain. Rather than the traditional adversarial “low-bid” model, many operators are now entering into long-term strategic partnerships with their key contractors. This approach encourages the early involvement of suppliers in the design process, allowing their expertise to be leveraged to optimize the construction and installation phases. Furthermore, the use of “performance-based contracts” where rewards are tied to the achievement of safety, schedule, and cost targets aligns the interests of all parties and fosters a culture of shared accountability. This shift in the commercial landscape is a vital solution to the persistent problem of project overruns.

The Human Element and Safety Performance in Project Execution

While technical and financial systems are essential, the success of any offshore project ultimately depends on the people who execute it. Maintaining a high level of safety performance across a diverse and often multinational workforce is a constant challenge. Offshore construction sites are hazardous environments, and the pressure to meet tight deadlines can sometimes lead to the erosion of safety standards. To prevent this, leading companies are fostering a “safety-first” culture that is supported by rigorous training, clear communication, and a commitment to “stop work authority” for every individual on the site.

The role of leadership in project delivery cannot be overstated. Managing the complex socio-technical system of an offshore project requires leaders who are not only technically proficient but also skilled in communication, conflict resolution, and change management. As projects become more digital and decentralized, the ability to maintain a cohesive team culture across different locations is vital. Investing in “soft skills” training for project managers and supervisors is increasingly recognized as a key component of successful offshore project execution challenges management. A well-led, motivated, and safety-conscious workforce is the most effective defense against the risks inherent in maritime construction.

Optimizing the Supply Chain and Logistical Resilience

The supply chain for an offshore project is a vast and fragile network that spans the globe. From the procurement of specialized steel and high-tech subsea valves to the chartering of massive heavy-lift vessels, any disruption in the logistics chain can have a devastating impact on the project schedule. Managing these supply chain risks requires a proactive approach that includes diversifying the supplier base, maintaining strategic buffers of critical components, and utilizing real-time tracking systems to monitor the movement of materials. The recent global supply chain disruptions have highlighted the need for greater resilience and flexibility in offshore project management.

Another emerging solution is the “local content” strategy, where operators invest in developing the capabilities of local suppliers and workforces in the regions where they operate. While this can sometimes be more expensive in the short term, it can provide significant long-term benefits in terms of reduced logistics costs, improved community relations, and a more stable political environment. By building a robust local ecosystem of service providers, companies can reduce their vulnerability to global disruptions and contribute to the sustainable economic development of host nations. This alignment of project goals with national interests is an increasingly important aspect of modern project execution.

The Future of Project Delivery in the Energy Transition

The move toward a lower-carbon energy system is also introducing new offshore project execution challenges. Projects are increasingly becoming “hybrid,” involving the integration of traditional oil and gas infrastructure with renewable energy sources like offshore wind or carbon capture systems. This complexity requires a new set of skills and a different approach to project management, focusing on the integration of disparate technologies and the management of multiple regulatory frameworks. Furthermore, the emphasis on sustainability means that the carbon footprint of the project execution phase itself including the emissions from construction vessels and fabrication yards is under increasing scrutiny.

The solution to these new challenges lies in continued innovation and the adoption of more agile project management methodologies. The industry is beginning to experiment with “lean” construction techniques and “modular” fabrication, which can significantly reduce waste and improve efficiency. As the offshore energy sector continues to evolve, the ability to execute projects that are not only cost-effective and safe but also sustainable will be the defining characteristic of successful operators. The focus on project delivery is shifting from a purely technical discipline to a holistic exercise in value creation that balances economic, social, and environmental goals.

Conclusion: Mastering Complexity for Sustainable Success

In conclusion, the successful management of offshore project execution challenges is fundamental to the future of the maritime energy industry. By embracing digital innovation, fostering collaborative commercial models, and maintaining a relentless focus on safety and cost control, companies can overcome the immense hurdles of the offshore environment. These solutions are not merely technical fixes; they represent a fundamental shift in the culture and business model of the sector, toward greater transparency, resilience, and efficiency.

As the industry pushes into deeper waters and navigates the complexities of the energy transition, the lessons learned from past project deliveries will be invaluable. The ability to execute projects with precision and predictability is the foundation upon which the industry’s social license and economic viability are built. By mastering the art and science of offshore project management, the sector will continue to provide the energy the world needs while setting new standards for industrial excellence and environmental responsibility. The journey is difficult, but the rewards of successful project delivery in terms of energy security, economic growth, and technological progress are well worth the effort.