The world’s energy system is at a crossroads, trying to balance the world’s endless need for fuel with the need to minimise greenhouse gas emissions. Oil and gas is the industry where this tension is most intense. It is both important for the development of the world and at the centre of the climate problem. Carbon capture in oil and gas, which is a way to make production cleaner, has gone from being a test notion to a key part of the industry’s plan to cut down on carbon emissions. As finance and innovation grow, carbon capture technologies are changing not only how hydrocarbons are made, but also how the whole life cycle of the resource is managed. This might lead to large cuts in emissions without sacrificing reliability or economic stability.

Why Change Is Necessary

The International Energy Agency (IEA) says that oil and gas production is responsible for about 15% of global energy-related emissions each year. This is a large part of the world’s carbon dioxide output. As more and more people want to reach net-zero emissions, big oil and gas companies are under more and more pressure from the government, the public, and their own finances to come up with ways to extract oil and gas more cleanly. Carbon capture in oil and gas is a genuine and scalable way to make production greener. It works by reducing emissions at the source, from the production wells to the processing plants.

These technologies help companies lower their greenhouse gas emissions while still providing the fuels and feedstocks that the world’s industries and transportation depend on by taking carbon dioxide out of the air before it gets there. According to the Global CCS Institute’s 2023 status report, there are already more than 40 commercial carbon capture and storage (CCS) facilities in operation throughout the world. These facilities capture more than 110 million tonnes of CO₂ every year, and this number is always going up as new projects become operational.

How Carbon Capture Technologies Work

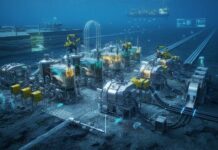

The carbon capture principle in oil and gas is a way to get more green extraction that isn’t hard but is technologically complex. Solvents, membranes, or adsorption are used to separate CO₂ emissions from other gases during oil and gas production. This commonly happens when natural gas is processed or when improved oil recovery is used. In refineries or petrochemical plants, post-combustion capture cleans up CO₂ from exhaust streams. Pre-combustion procedures deal with emissions that happen while hydrogen or syngas is made.

After being separated, the trapped CO₂ is compressed and either employed in industrial processes, such as increased oil recovery or making chemicals and fuels, or injected into deep geological formations for long-term storage. The North Sea, the Gulf Coast, and areas of the Middle East have all become important places for this kind of storage, employing empty reservoirs and salty aquifers.

Scaling Carbon Capture: Power Deals and Renewable Energy

Carbon capture in oil and gas is a necessary tool for cleaner extraction, but the use of this energy-hungry technology raises serious concerns about the long-term sustainability of power supply. To run large capture plants, compressors, and pipeline systems, they need a lot of electricity all the time, and it should have as little excess carbon as possible. This has led to a lot of new power arrangements, especially those that combine run-of-river hydro with pumped-storage to give heavy industrial and even capture sites steady, dispatchable energy.

The Economy and the Rules

The price of carbon capture in oil and gas, which is a way to get cleaner oil and gas, has gone down a lot in the last ten years. This is because of economies of scale, regulatory support, and new technologies. Early facilities might cost $70–$100 per tonne of CO₂ absorbed, but many projects now report prices in the $40–$60 per tonne range. prices are likely to go down even further as new capture materials, modular designs, and digital monitoring systems are used.

Governments and institutions have played a big role in speeding up deployment. For example, the United States’ Inflation Reduction Act enhanced tax credits for CCS to $85 per tonne. The European Union, on the other hand, has set aside billions of euros for its Innovation Fund. The incentives, along with stricter emissions rules and the introduction of carbon pricing, have changed the game for big oil and gas companies. CCS is now a strategic investment instead of just a way to meet laws.

Challenges and the Way Forward

Carbon capture in oil and gas as a tool for cleaner extraction also has problems. To use it on a large scale, you need to spend a lot of money at first, get public support for CO₂ storage sites, and have strict policies to ensure safety and openness. There are also worries about whether CCS can be scaled up to meet the huge cuts in emissions that need to be made. By 2050, global targets call for capturing a number of gigatonnes of CO₂ each year.

But the faster pace of pilot initiatives, business alliances, and cooperation between other industries gives us hope. The oil and gas industry is showing that realistic, technology-based solutions may make a significant difference by combining CCS with renewable energy supply contracts and coupling it to the natural properties of hydro and storage.

Conclusion

Carbon capture in oil and gas is a technique for cleaner extraction that is changing how the sector responds to climate change. The oil and gas business are getting ready for a time of lower-carbon extraction by adding more facilities and improving the way that renewables and CCS work together. The alignment of technology, economics, and policy will still be vital, but the path is clear: carbon capture has gone from a theoretical fix to a real, necessary aspect of global energy policy. This reform is a big step towards reconciling energy security with environmental responsibility for an industry that has never been looked at so closely before.