The offshore oil and gas industry remains one of the most challenging and technologically demanding sectors globally. The harsh environmental conditions, high operational costs, safety concerns, and the complexity of managing vast infrastructure necessitate innovative solutions for maintenance and operational efficiency. One of the most revolutionary developments in recent times has been integrating Artificial Intelligence (AI) for predictive maintenance, especially designed to be used on offshore platforms. With advancements in technological capabilities, AI-based predictive maintenance is proving to be a game-changer, saving time, streamlining resource utilization, and increasing safety levels.

Need for Predictive Maintenance in Offshore Platforms

Offshore platforms operate under some of the most extreme conditions on Earth, exposed to high-pressure environments, corrosive seawater, unpredictable weather patterns, and mechanical stresses. These factors make maintenance a difficult, costly, and high-stakes task. Traditionally, maintenance practices relied on scheduled inspections and reactive repairs, often leading to unplanned outages and costly downtimes.

The risk of equipment failure in such environments is significant, risking not only operational loss but also safety hazards and environmental damage. The high cost of offshore maintenance, combined with the imperative to keep assets operational, has driven the industry to seek smarter, data-driven approaches.

The convergence of IoT sensors, big data, and AI algorithms is transforming maintenance from a reactive or time-based activity into a proactive, intelligent process.

The Technological Foundations of AI-Powered Predictive Maintenance

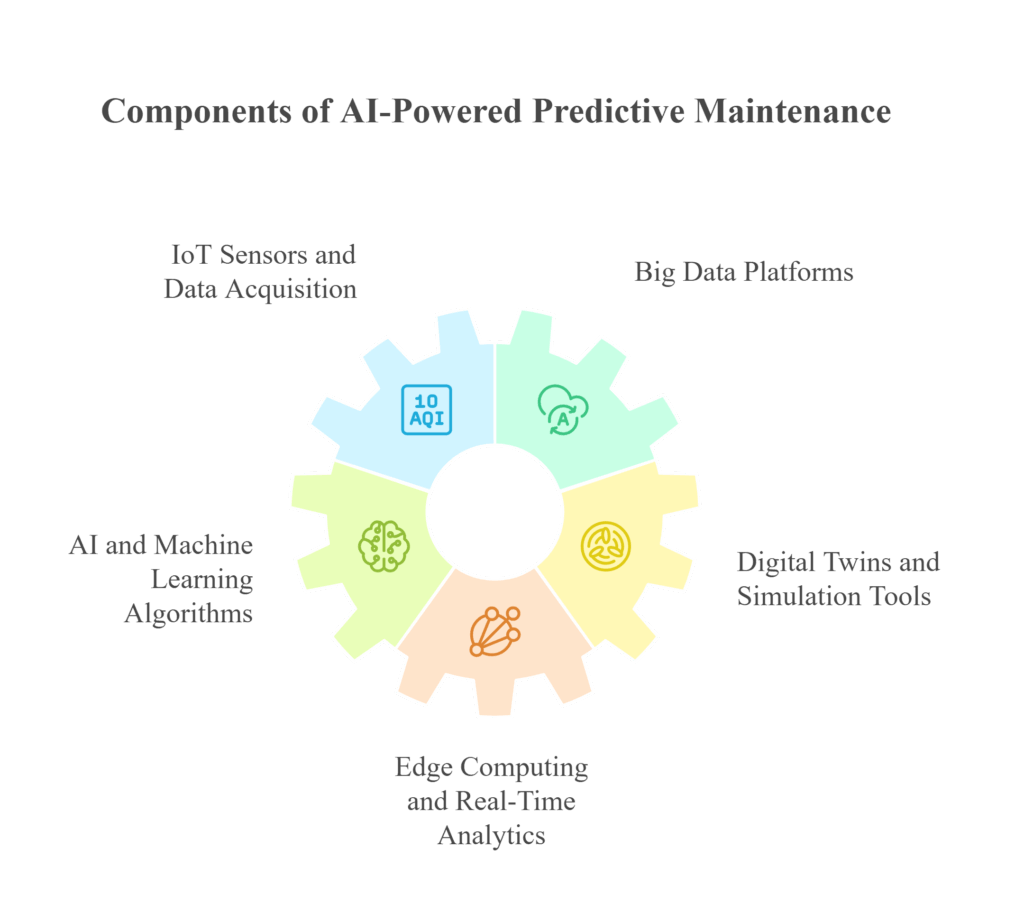

Implementing AI-driven predictive maintenance requires a robust technological infrastructure, composed of several interconnected elements. These technologies work synergistically, enabling offshore platforms to harness vast amounts of data, analyze complex patterns, and generate actionable insights.

- IoT Sensors and Data Acquisition

At the core are IoT sensors installed on critical equipment such as pumps, turbines, valves, and structural components. These sensors continuously monitor parameters like vibration, temperature, pressure, humidity, and acoustic signals. Given the corrosive saltwater environment, sensors are designed to withstand harsh conditions, ensuring data integrity over extended periods. The continuous data flow from these sensors creates a comprehensive operational picture of the platform’s assets.

- Big Data Platforms

The massive influx of sensor data necessitates advanced data management solutions. Cloud-based or hybrid big data platforms store, process, and pre-aggregate data streams, enabling real-time and historical analysis. These platforms facilitate data cleansing, normalizations, and storage of large datasets needed for AI models to operate effectively.

- AI and Machine Learning Algorithms

AI algorithms—especially machine learning models—train on historical and real-time data to identify patterns indicating potential failure modes. These models analyse correlations between various parameters and equipment health, learning to distinguish normal operational signatures from anomalies signaling possible issues. Over time, models improve their predictive accuracy, adapting to evolving operational conditions.

- Digital Twins and Simulation Tools

Digital twins—virtual replicas of physical equipment—play an increasingly significant role, allowing operators to simulate equipment behavior under different scenarios. AI-powered digital twins help visualize potential failures, optimize maintenance schedules, and simulate the impact of repairs, thereby refining predictive analytics.

- Edge Computing and Real-Time Analytics

Given the remote nature of offshore platforms, edge computing enables local data processing, reducing latency and bandwidth demands. Critical alerts and predictions can be generated in real-time at the platform level, ensuring immediate response capabilities even in low-connectivity scenarios.

Benefits of AI-Powered Predictive Maintenance on Offshore Platforms

The integration of AI in maintenance processes yields numerous benefits that directly impact operational efficiency, safety, and profitability. Foremost is the significant reduction in unplanned outages. Predictive analytics detect signs of equipment degradation long before failure, allowing planned interventions that minimise downtime and operational disruptions.

Cost savings constitute a major advantage. Traditional maintenance schedules—based solely on fixed intervals—often lead to unnecessary inspections or repairs. AI’s predictive capabilities allow for just-in-time interventions, cutting down unnecessary costs. Long-term asset health is also improved through early fault detection, preventing the failures that can be expensive and hazardous.

Safety risks are substantially reduced, as AI systems can automatically flag hazardous conditions, trigger safety protocols, or even initiate emergency shutdowns if critical thresholds are exceeded. This proactive approach enhances the safety culture onboard, protecting personnel and the environment.

Moreover, AI-driven predictive maintenance offers an unparalleled level of operational transparency. Real-time dashboards and predictive alerts enable decision-makers to optimise maintenance workflows, allocate resources efficiently, and plan logistics with precision. Combining these insights with automated scheduling tools results in more organized, efficient operations.

Challenges in Deploying AI-Driven Predictive Maintenance for Offshore Platforms

While the advantages are compelling, deploying AI-powered predictive maintenance in offshore environments presents unique challenges.

Connectivity remains a hurdle. Remote offshore platforms often experience limited or intermittent satellite communication, complicating real-time data transmission and management. Implementing edge computing solutions becomes essential, but deploying these systems requires significant planning and investment.

Data quality and quantity also impact AI effectiveness. Inconsistent data streams, sensor malfunctions, or gaps in historical data can undermine model accuracy. Addressing these issues requires rigorous calibration, ongoing maintenance, and sophisticated data processing.

Cybersecurity is a growing concern. As data and control systems become interconnected, ensuring the security of these assets against cyber threats is paramount. Implementing rigorous security protocols, timely updates, and threat detection mechanisms are non-negotiable in maintaining operational integrity.

Organisational change management is equally critical. Moving from traditional maintenance schedules to an AI-driven approach demands workforce training, cultural shifts, and operational adjustments. Resistance to change can lead to successful adoption, making leadership and clear communication vital.

Moreover, regulatory and compliance considerations must be incorporated into the deployment strategy, with clear standards aligned with industry best practices to ensure safety and environmental protection.

Conclusion: The Future of Offshore Maintenance

AI-powered predictive maintenance is revolutionising offshore platform management, combining advanced data analytics, intelligent algorithms, and autonomous systems. This delivers unprecedented operational efficiencies, safety improvements, and cost reductions. As the offshore industry continues to evolve amidst increasing environmental challenges and economic pressures, adopting AI-driven solutions is no longer optional but essential.

By leveraging real-time insights and predictive analytics, offshore operators can anticipate failures, optimize maintenance schedules, and deploy resources more effectively. This proactive approach not only maximizes asset longevity and performance but also safeguards the environment, reinforcing the industry’s commitment to safety and sustainability.