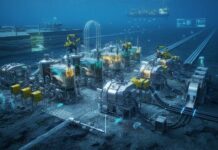

The offshore energy industry operates in some of the most challenging and high-risk environments on the planet, where the margin for error is non-existent. In this context, the protection of human life is not just a moral obligation but the very foundation of operational viability. This has led to the development of rigorous offshore workforce safety standards and comprehensive competency frameworks that govern every aspect of maritime work. As technology becomes more complex and the industry moves into deeper, more remote waters, the focus on workforce readiness has shifted from basic compliance to a sophisticated, data-driven discipline that emphasizes both technical skill and psychological resilience.

The modern approach to offshore safety management is built on the philosophy that every incident is preventable. This requires a multi-layered strategy that combines engineering controls, digital monitoring, and a highly trained workforce. The goal is to create a “chronic unease” a culture where every individual, from the deckhand to the installation manager, is constantly vigilant for potential hazards. By aligning individual skills with standardized offshore competency programs, the industry is ensuring that its people are not only capable of performing their duties safely but are also empowered to challenge unsafe practices and drive continuous improvement in HSE offshore performance.

The Evolution of Oil Gas Workforce Training and Simulation

High-quality training is the first line of defense against offshore accidents. Historically, oil gas workforce training relied heavily on classroom-based learning and on-the-job apprenticeship. Today, however, the industry has embraced high-fidelity simulation and immersive virtual reality (VR) to prepare workers for the realities of offshore life. Simulators allow personnel to practice complex tasks such as well control, heavy-lift operations, or emergency helicopter evacuations in a safe, controlled environment. This “muscle memory” is vital for ensuring that workers can act with technical precision during high-pressure situations where a single wrong move could have catastrophic consequences.

Furthermore, standardized training protocols, such as those established by OPITO, have created a global language of safety. These standards ensure that a worker trained in the North Sea possesses the same foundational safety skills as one working in the Gulf of Mexico or offshore Asia. This global consistency is essential for an industry characterized by a highly mobile and multinational workforce. By adhering to these internationally recognized offshore workforce safety standards, companies can ensure a seamless transition of personnel across different assets, maintaining a high and predictable level of safety performance regardless of the geographical location of the project.

The Role of Digital Systems in Competency Management

Managing the competency of thousands of workers across multiple remote locations is a massive logistical challenge. The traditional method of tracking paper certificates and training records has given way to integrated digital competency management systems. These platforms allow for the real-time tracking of every individual’s training status, certifications, and on-site performance. If a worker’s “HUET” (Helicopter Underwater Escape Training) is about to expire, the system can automatically flag this to management and prevent them from being assigned to a departing flight until the training is renewed. This level of automated oversight is a critical component of modern offshore safety management.

Digital systems also facilitate more personalized and continuous learning. Rather than waiting for a periodic refresher course, workers can access bite-sized training modules and safety alerts directly on their mobile devices or platform-based kiosks. This “just-in-time” learning keeps safety at the forefront of the worker’s mind and allows for the rapid dissemination of lessons learned from incidents occurring elsewhere in the industry. Furthermore, the use of wearable technology is beginning to provide data on worker fatigue and environmental exposure, allowing for more proactive offshore risk reduction by managing the physical and mental well-being of the workforce in real-time.

Integrating Human Factors into HSE Offshore Strategies

The realization that over 80% of industrial accidents have a “human factor” component has led to a significant shift in how HSE offshore strategies are designed. Modern safety standards now place a heavy emphasis on non-technical skills, such as communication, leadership, and situational awareness. This focus on “human performance” acknowledges that even the most technically competent worker can make a mistake if they are fatigued, stressed, or operating in a poorly designed workspace. By training teams to work more effectively together and to recognize the early signs of cognitive failure, the industry is building a deeper layer of resilience into its operations.

Psychological safety is also emerging as a key pillar of offshore workforce safety standards. This refers to an environment where workers feel safe to speak up about mistakes or to question a superior’s decision without fear of retribution. In a high-stakes environment like an offshore platform, the “silence of the crew” can be deadly. Fostering a culture where open communication is rewarded and where “stop work authority” is genuinely supported is essential for preventing the normalization of deviance. This cultural transformation is perhaps the most difficult aspect of safety management, but it is the one that yields the greatest long-term results in terms of risk reduction and operational excellence.

Standardizing Competency for the Energy Transition

As the offshore sector evolves to include more renewable energy and carbon capture projects, the definition of competency is expanding. The workforce of the future must be skilled in a wider range of technologies, from high-voltage electrical systems for offshore wind to the specialized handling of CO2 for sequestration. Offshore competency programs are currently being updated to bridge this “skills gap,” ensuring that the maritime expertise of the traditional oil and gas sector is transferred to the emerging green energy economy. This transition provides a unique opportunity to harmonize safety standards across all offshore sectors, creating a single, robust framework for all maritime energy work.

The role of contractors in the safety chain is also receiving increased scrutiny. Many offshore projects rely heavily on third-party service providers, and ensuring that these contractors meet the same high offshore workforce safety standards as the operator is a major priority. This requires a collaborative approach to safety management, where operators and contractors share data, align their training protocols, and conduct joint safety audits. By treating the entire offshore workforce as a single, integrated team, the industry can eliminate the “interface risks” that often lead to incidents and ensure a consistent culture of safety across the entire value chain.

The Economic Case for Superior Safety Performance

Beyond the moral and legal imperatives, there is a compelling economic case for maintaining the highest possible offshore workforce safety standards. Accidents are incredibly expensive, involving not only the cost of remediation and compensation but also the massive loss of production and the erosion of a company’s market value. Furthermore, a strong safety record is a prerequisite for securing insurance, project financing, and the support of host governments. In a competitive global market, companies with a reputation for safety and competency are better positioned to win new contracts and to attract the most talented workers.

Investing in safety and competency is, therefore, a strategic investment in the long-term profitability and resilience of the business. Companies that view safety as a cost center to be minimized are increasingly finding themselves at a disadvantage compared to those that view safety as a core value and a driver of operational efficiency. A well-trained, competent, and safety-conscious workforce is more productive, more innovative, and more capable of navigating the complexities of modern energy development. The focus on offshore risk reduction is effectively a focus on the sustainability of the entire enterprise.

Conclusion: Leading with Safety in a Changing World

In conclusion, the continuous improvement of offshore workforce safety and competency standards is the most important mission of the maritime energy sector. By embracing advanced simulation, digital management systems, and a deep understanding of human factors, the industry is creating a safer and more professional environment for the thousands of people who work at sea. The transition to a more integrated and transparent culture of safety is essential for meeting the challenges of the future and for maintaining the public’s trust.

As the industry continues to innovate, the focus must remain on the individual worker. The most advanced technology in the world is useless without a competent and empowered person to operate it. By valuing its people as its most important asset and by providing them with the tools, training, and support they need to work safely, the offshore sector is ensuring its continued success for generations to come. The goal of “zero harm” is not just a slogan; it is a measurable objective that is being achieved through the relentless pursuit of excellence in every aspect of workforce safety and competency.