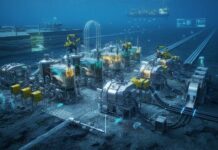

The offshore energy industry has entered a new era where data is no longer a byproduct of operations but its primary strategic engine. In the past, offshore platforms were relatively isolated outposts, generating vast amounts of information that was often siloed within specific departments or physical hard drives on-site. Today, however, the rise of integrated offshore data platforms is fundamentally changing this dynamic. These sophisticated systems are designed to ingest, process, and analyze information from across the entire value chain from subsea sensors and platform machinery to logistical networks and reservoir models. The result is a unified, real-time digital representation of the offshore environment that empowers decision-makers with unprecedented clarity and speed.

The move toward a digital oilfield offshore is driven by the increasing complexity of modern projects and the relentless pressure to improve efficiency and safety. In deepwater environments, where a single day of downtime can cost millions of dollars, the ability to identify and mitigate risks before they occur is a critical survival trait. Integrated offshore data platforms provide the necessary “connective tissue” to link disparate data streams into a cohesive whole, allowing for a more holistic and proactive approach to asset management. This digital transformation is not merely about more data; it is about better data, delivered to the right people at the right time in an actionable format.

The Core of Offshore Data Integration and Unification

At the heart of any successful digital transformation is the process of offshore data integration. This involves breaking down the technical and organizational silos that have historically fragmented information in the energy sector. Modern platforms use cloud-based architectures and standardized data protocols to ensure that information from different equipment manufacturers and software systems can “talk” to each other. This unification is essential for creating a “single source of truth” that is accessible to everyone from the offshore installation manager to the onshore reservoir engineer. By eliminating the need for manual data entry and reconciliation, integrated offshore data platforms significantly reduce the risk of error and speed up the cycle of operational decision-making.

Furthermore, the integration of data from diverse sources allows for the discovery of correlations that were previously invisible. For example, by linking weather data with vessel coordination and platform power consumption, an operator can identify patterns that optimize fuel usage during supply runs. Or, by correlating subsea pressure readings with chemical injection rates, engineers can fine-tune the dosage to prevent hydrate formation while minimizing chemical costs. This level of cross-functional visibility is a hallmark of the digital oilfield offshore, turning what was once “noise” into a powerful source of operational intelligence.

Leveraging Reservoir Data Systems for Precision Management

One of the most impactful applications of integrated data is in the realm of reservoir management. Traditional reservoir models were often “static,” updated only periodically as new seismic or drilling data became available. Modern integrated offshore data platforms utilize “dynamic” reservoir data systems that are fed by real-time production figures and pressure readings. This allows for the creation of “living” models that continuously adapt to reflect the actual behavior of the reservoir. By using these models to run “what-if” simulations, operators can optimize the placement of new wells and the execution of enhanced oil recovery (EOR) strategies with a much higher degree of confidence.

The precision offered by these systems is vital for maximizing the recovery factor of a field over its entire life. In mature basins, where reservoirs are more depleted and technically challenging, the margin for error is slim. Integrated data allows for the surgical management of flow rates and injection profiles, ensuring that every barrel is extracted as efficiently as possible. Additionally, the ability to share these reservoir insights in real-time with global teams of experts ensures that the best geological and engineering knowledge is always applied to the most critical decisions. This “democratization” of data is a major benefit of modern offshore analytics platforms.

The Power of Offshore AI Insights and Predictive Analytics

The massive volume of data generated by an offshore asset would be overwhelming without the aid of artificial intelligence. Modern offshore analytics platforms use machine learning algorithms to sift through terabytes of information, identifying subtle trends and anomalies that indicate a potential problem. These offshore AI insights provide a “predictive” layer to operations, moving away from a traditional “break-fix” maintenance model toward one based on the actual condition and risk profile of the equipment. For instance, an AI model can detect the early signs of bearing failure in a high-pressure pump weeks before it actually fails, allowing for a planned repair during scheduled downtime.

AI also plays a critical role in enhancing safety and environmental performance. Predictive models can monitor satellite and sensor data to detect methane leaks or oil spills with extreme accuracy, enabling a rapid and effective response. In the realm of well integrity, AI can analyze historical drilling data to predict potential geomechanical hazards, allowing drillers to adjust their parameters in real-time to prevent blowouts or wellbore collapse. This synergy between human expertise and machine intelligence is creating a safer, more resilient offshore environment. The goal of integrated offshore data platforms is not to replace human decision-making, but to augment it with a level of precision and foresight that was previously unattainable.

Overcoming the Technical Barriers to Data Integration

Despite the clear benefits, the implementation of integrated offshore data platforms is not without its challenges. One of the primary hurdles is the “legacy system” issue older equipment that was never designed to be part of a connected digital network. Retrofitting these assets with the necessary sensors and communication tools can be a complex and expensive task. Furthermore, the remote location of offshore assets means that high-speed, reliable connectivity is a constant challenge. The adoption of low-earth-orbit (LEO) satellite constellations and 5G maritime networks is helping to overcome these bandwidth limitations, but ensuring consistent data flow remains a top priority for IT teams.

Cybersecurity is another critical concern for the digital oilfield offshore. As assets become more connected and accessible from shore, they also become more vulnerable to cyber threats. Protecting the integrity of the data and the safety of the operations requires a robust, multi-layered security strategy that includes everything from encrypted data transmission to strict access controls and continuous threat monitoring. Finally, there is the organizational challenge of “data culture.” Successfully leveraging integrated data requires a shift in mindset, where data is viewed as a strategic asset and where employees are trained to use analytics as a core part of their daily workflow. Managing this cultural change is as important as the technology itself.

The Future: From Integrated Data to Autonomous Operations

The ultimate trajectory of integrated offshore data platforms is toward more autonomous operations. As AI models become more sophisticated and data integration more seamless, we are seeing the rise of “self-optimizing” systems that can adjust their own parameters in real-time without human intervention. For example, a subsea processing system could automatically adjust its separation efficiency based on changes in the incoming fluid composition. Or, an automated power management system could balance the supply from offshore wind turbines and gas generators to minimize emissions while ensuring grid stability.

This move toward autonomy does not mean the end of human involvement; rather, it shifts the human role toward high-level strategy and oversight. Engineers will spend less time on routine monitoring and data reconciliation and more time on complex problem-solving and long-term asset optimization. The digital oilfield offshore will eventually become a highly intelligent, self-healing network that is more efficient, safer, and more sustainable than any traditional operation. The foundation for this future is being laid today through the deployment of integrated offshore data platforms and the relentless pursuit of digital excellence.

Conclusion: Data as the New Offshore Currency

In conclusion, the adoption of integrated offshore data platforms is a transformative step for the maritime energy sector. By unifying disparate data streams, leveraging predictive analytics, and providing real-time reservoir insights, these systems are enabling a more precise and proactive approach to decision-making. The transition to a data-driven operational model is essential for navigating the complexities of deepwater production and the challenges of the energy transition.

The success of the industry’s digital journey will depend on its ability to embrace new technologies, foster a culture of data literacy, and maintain the highest standards of cybersecurity. As the world’s energy needs continue to evolve, the companies that thrive will be those that view data as their most valuable asset. The platforms of the future will be more than just steel and machinery; they will be intelligent, connected nodes in a global energy network that is smarter, safer, and more sustainable for everyone. The digital revolution in the offshore space is just beginning, and its potential to reshape the industry is limitless.