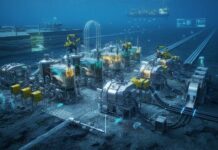

The success of offshore energy production is inextricably linked to the efficiency and resilience of the supply chains that sustain it. In the remote and often hostile environments where offshore assets operate, the ability to deliver equipment, food, fuel, and personnel with pinpoint accuracy is not just an operational requirement it is a critical safety and economic mandate. This has led to the development of advanced marine logistics supporting offshore platforms, a specialized discipline that blends maritime expertise with cutting-edge digital technology. As projects move further offshore and into deeper waters, the logistical “tail” becomes longer and more complex, requiring a fundamental shift from traditional scheduling to integrated, data-driven management.

The core of modern offshore marine logistics is the synchronization of land-based warehouses, port facilities, and a diverse fleet of specialized vessels. Every delay in this chain can have a cascading effect, potentially leading to millions of dollars in lost production or compromising the safety of the offshore workforce. Consequently, the industry is increasingly adopting “lean” logistics principles, focusing on the elimination of waste and the optimization of every vessel movement. By treating the entire logistical network as a single, connected ecosystem, operators can achieve a level of offshore supply reliability that was previously considered impossible in the maritime environment.

The Evolution of Offshore Support Vessels and Specialized Fleets

At the heart of any marine energy logistics operation is the fleet of offshore support vessels (OSVs). These vessels are the workhorses of the industry, performing a wide range of tasks from towing and anchor handling to subsea construction and emergency response. Among these, platform supply vessels (PSVs) are perhaps the most critical for day-to-day operations. Modern PSVs are designed for maximum cargo capacity and fuel efficiency, featuring sophisticated dynamic positioning (DP) systems that allow them to hold station within meters of a platform in high seas. This capability is essential for the safe transfer of deck cargo, fuel, and bulk materials such as cement and drilling mud.

The design of OSVs is continuously evolving to meet the demands of deeper water and more complex projects. Multi-purpose vessels that can switch between supply, subsea intervention, and personnel transport are becoming increasingly popular, as they offer greater flexibility and better fleet utilization. Furthermore, the push for offshore sustainability is driving the development of “green” OSVs powered by LNG, hydrogen, or battery-hybrid systems. These advanced marine logistics supporting offshore platforms not only reduce the carbon footprint of the production cycle but also provide a quieter and more efficient working environment, demonstrating that environmental responsibility and operational excellence can go hand in hand.

Optimizing Vessel Coordination through Digital Integration

The transition from manual scheduling to advanced marine logistics offshore platforms is powered by digital integration. Modern logistics hubs now use cloud-based platforms to track the real-time position and status of every vessel in the fleet, as well as the location of every piece of cargo in the supply chain. This visibility allows for “just-in-time” delivery models, where supplies are dispatched only when they are needed, reducing the need for expensive storage space on the offshore platform. By using AI-driven algorithms to optimize vessel routes and schedules, operators can significantly reduce fuel consumption and minimize the time vessels spend idling at sea.

Digitalization also extends to the management of the cargo itself. The use of RFID tags and IoT sensors allows for the automated tracking of equipment as it moves from the manufacturer to the offshore site. This ensures that the right parts are delivered to the right platform at the right time, virtually eliminating the risk of “missing cargo” that has historically plagued offshore operations. Furthermore, the integration of these tracking systems with the platform’s maintenance management software allows for the automated triggering of supply orders based on actual equipment usage and condition. This level of connectivity is a cornerstone of the modern digital oilfield, turning marine energy logistics into a strategic asset.

Enhancing Offshore Supply Reliability and Risk Management

The primary challenge for any offshore logistics operation is the management of risk, particularly the risks associated with weather and sea conditions. Advanced marine logistics supporting offshore platforms involves the use of high-resolution weather forecasting and maritime motion sensors to predict the “operational window” for cargo transfers. If the conditions are too rough, the system can automatically reschedule vessel movements to minimize downtime and prevent accidents. This proactive approach to safety is essential for protecting both the personnel involved in the transfer and the integrity of the expensive equipment being handled.

Risk management also involves the creation of redundant and resilient supply chains. This might include maintaining a pool of “shared” vessels among multiple operators in a region or developing alternative port facilities that can be used in the event of a localized disruption. The recent global supply chain challenges have highlighted the importance of this resilience, prompting many companies to invest more heavily in their offshore transport systems and regional supply hubs. By building flexibility into the logistical network, operators can ensure offshore supply reliability even in the face of major geopolitical or environmental shocks, safeguarding the continuity of energy production.

The Role of Personnel Transport and Marine Aviation

While cargo is vital, the transport of personnel is perhaps the most sensitive aspect of marine energy logistics. Historically, helicopters have been the primary mode of transport for offshore crews, but their high cost and vulnerability to weather have led to an increase in the use of specialized “walk-to-work” vessels. These vessels are equipped with heave-compensated gangways that allow workers to walk safely from the ship to the platform even in significant wave heights. This approach provides a safer and more comfortable alternative to traditional boat transfers or helicopter flights, and it is becoming a standard feature of advanced marine logistics supporting offshore platforms.

The integration of marine and aviation logistics into a single, unified management system is also gaining traction. By coordinating helicopter flights with vessel movements, operators can ensure that crews and equipment arrive at the platform simultaneously, minimizing the time spent waiting for “all-clear” signals. This holistic view of personnel transport improves the efficiency of crew changes and emergency evacuations, contributing to a more responsive and safe offshore environment. As technology continues to advance, the use of autonomous drones for light cargo and personnel transport is also being explored, promising even greater flexibility for future offshore transport systems.

Streamlining Cargo Handling and Port Operations

The efficiency of advanced marine logistics offshore platforms is often determined at the port. Modern offshore supply bases are designed for rapid turnaround, featuring dedicated berths for different types of vessels and automated cargo handling systems. The use of standardized “mini-containers” and specialized bulk-handling equipment allows for the faster loading and unloading of PSVs, reducing the time vessels spend in port and increasing their overall productivity. By optimizing the “shore-to-ship” interface, logistics managers can ensure that the maritime leg of the journey begins on the best possible footing.

Digitalization is also transforming port operations, with “smart ports” using automated gate systems and real-time inventory management to reduce congestion and improve transparency. The synchronization of port activity with vessel schedules ensures that berths are always available when needed and that cargo is ready for immediate loading upon the vessel’s arrival. This level of operational precision is essential for supporting the fast-paced nature of modern offshore projects, where every hour of delay in port translates into increased costs and potential risks to the production schedule. The port is no longer just a stopping point; it is a critical engine of marine energy logistics.

Conclusion: The Future of Maritime Supply Chains

In conclusion, the development of advanced marine logistics supporting offshore platforms is a vital driver of the industry’s continued success in deep and remote waters. By leveraging offshore support vessels, digital integration, and sophisticated risk management, operators are building a more resilient and efficient infrastructure for global energy production. The transition to a data-driven logistical model is not only improving the bottom line but also enhancing the safety and environmental performance of the entire maritime sector.

As the industry continues to evolve, the focus must remain on the integration of disparate systems into a single, cohesive network of marine energy logistics. The challenges of the future from the energy transition to increasing geopolitical volatility will require even greater levels of agility and transparency. By investing in new technologies and fostering a culture of continuous improvement, the offshore logistics sector will continue to provide the reliable foundation upon which the world’s energy security is built. The horizon of maritime supply is expanding, and the advanced logistics systems of today are the key to unlocking the potential of tomorrow.